BL-Pressing and blanking production line

Key word: BL-Pressing and blanking production line

Category:

Product Details

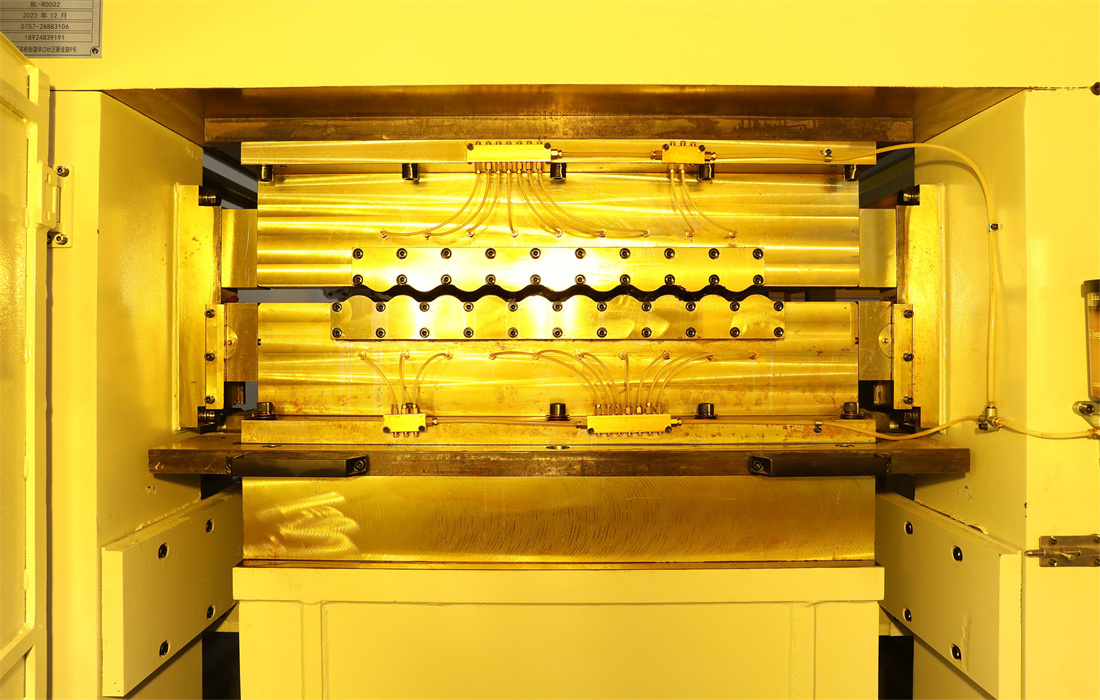

| ● High-quality flatness | |

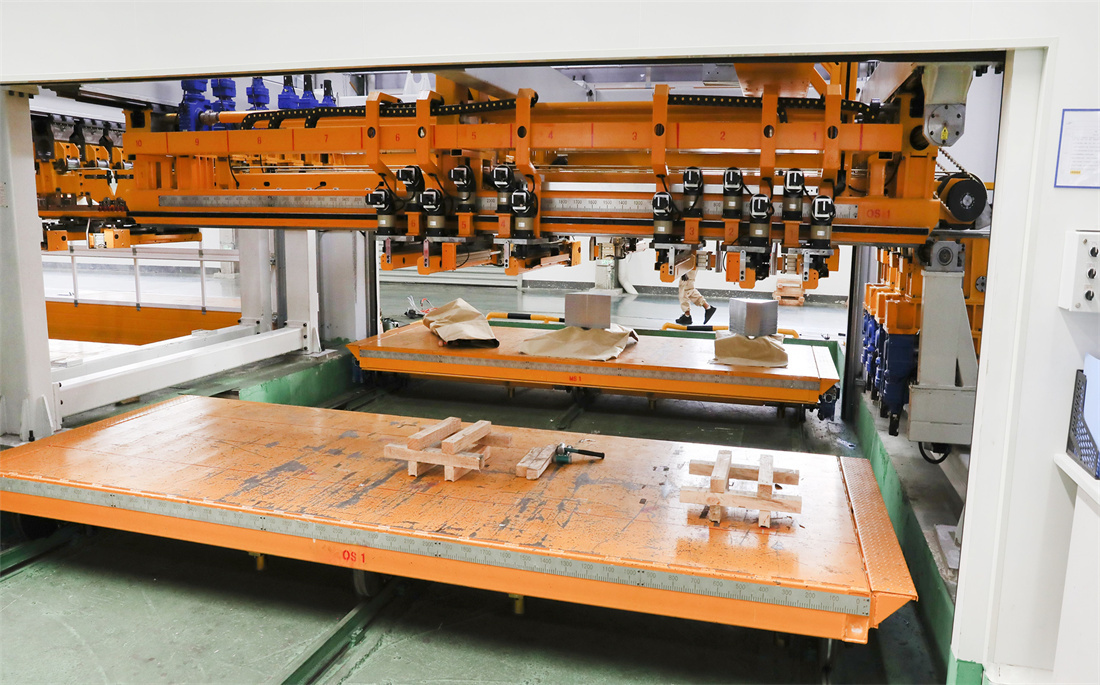

| ● High-precision length setting, high speed, high-precision feeding | |

| ● Effective scratch prevention measures | |

| ● Neat stacking | |

| ● Simple and convenient maintenance | |

| ● Stable and reliable machine performance |

| ● Specifically for automotive exterior panels, aluminum products, and other products with high surface quality requirements |

| ● Product Model: 1850 2050 2150 | |

| ● Applicable Materials: Cold-rolled steel sheet, galvanized aluminum sheet, aluminum sheet, etc. | |

| ● Material Width: 500-1850 mm 500-2050 mm 500-2150 mm | |

| ● Material Thickness: 0.5-3.0 mm 0.5-3.0 mm 0.5-3.0 mm | |

| ● Coil Weight: 25 ton ( Max.) 30 ton ( Max.) 30 ton ( Max.) | |

| ● Feeding Accuracy : ±0.2 mm/m ±0.2 mm/m ±0.2 mm/m | |

| ● Feeding Speed :180 m/min( Max.) 180 m/min( Max.) 180 m/min( Max.) | |

| ● Unit Speed: 90 m/min 90 m/min 90 m/min | |

| ● Stacking Weight: 10 ton 10 ton 10 ton |

Factory Advantages

Based on laser CNC technology Focus on coil blanking technology

We are committed to independent innovation and have formed complete independent intellectual property rights in the fields of CNC systems, laser blanking, and metal sheet forming machine tools.

We are committed to developing and creating cutting-edge products in the industry, aiming to become a leader in laser blanking equipment and technology.

Complete independent intellectual property rights, obtained a number of key core patents, the company's main product laser dynamic continuous cutting machine was awarded the high-tech product title by Guangdong Province

Related Products