With the biting north wind and rolling cold currents, temperatures across the country continue to drop, especially in the north, where icy snow and sub-zero temperatures prevail. The first fully automatic, dynamic, continuous laser blanking production line in Northwest China—Kudi No. 2 Machinery's CEP001—has been operating smoothly since its acceptance and commissioning in 2019, enduring both winter's harsh cold and summer's scorching heat.

This CEP001 continuous blanking production line, purchased by Hunan Wujiang Light Chemical Group Co., Ltd., was built and commissioned in Hami, Xinjiang, and is mainly used for mass production of composite metal products. Since its launch, the equipment has operated smoothly year-round, earning high praise from the customer.

Due to the production line's advantages of durability, high efficiency, low consumption, energy saving, environmental protection, and labor saving, Wujiang Group placed a follow-up order. Kudi No. 2 Machinery and Wujiang Group have now become close partners.

Kudi No. 2 Machinery, committed to becoming a leader in the field of laser continuous blanking equipment, continues to focus on laser CNC technology and uncoiling blanking processes, forming its unique technological advantages:

01

Uses variable-speed feeding technology to ensure both high productivity and blanking accuracy.

02

The feeding machine uses dual servo motor drive to accurately compensate for feeding errors and prevent feeding deviation.

03

The cutting machine uses belt support to avoid scratching the surface of the blanked parts.

04

The support belt of the cutting machine forms a moving light seam under the cutting head, preventing slag from forming on the edges of the blanked parts.

05

Stacking tables adapt to various product specifications and can be quickly adjusted during product switching.

06

Precise feeding and waste separation processes ensure high accuracy and reliability of stacking.

07

Uses professional nesting software suitable for continuous cutting, resulting in high material utilization.

To date, Kudi No. 2 Machinery has formed a series of product systems with patented inventions and innovative technologies as its core competitive advantages, capable of providing customized solutions to meet the needs of various industrial enterprises, including automotive interior and exterior sheet metal, steel distribution, cookware, home appliances, sanitary ware, and tableware.

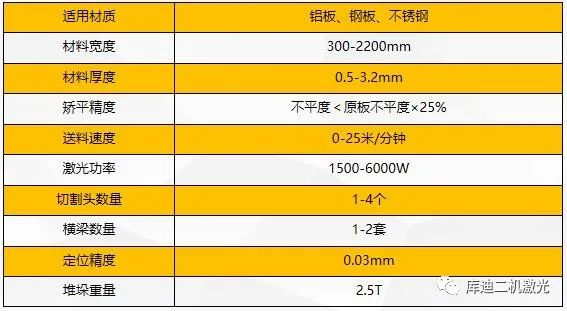

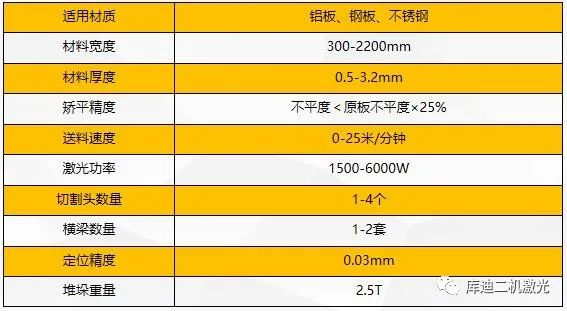

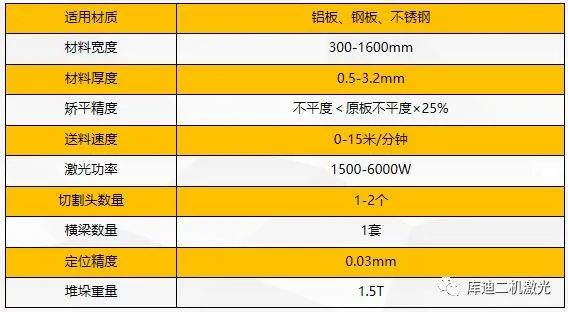

CEP001 Belt-Supported Laser Continuous Blanking Production Line

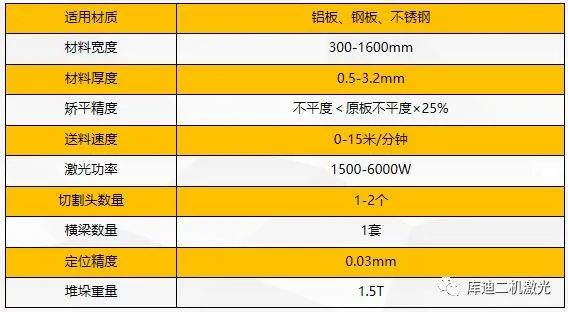

CEP002 Reciprocating Laser Continuous Blanking Production Line

While continuously innovating, Kudi No. 2 Machinery has also reserved upgrade windows for existing equipment, meaning that Kudi No. 2 Machinery's equipment is always upgradeable and at the forefront of technology.

Kudi No. 2 Machinery's factory workshop has physical production lines for CEP001 and CEP002, where you can observe the equipment's actual operation.

Welcome to visit our factory for discussions and experience firsthand the hard-core strength of Kudi No. 2 Machinery's laser blanking equipment, where both appearance and talent are online.

With biting north winds and rolling cold fronts, temperatures across the country continue to drop, especially in the north, where icy conditions and snow prevail, with temperatures consistently below zero. The northwest region's first fully automatic, dynamic, continuous laser blanking production line—Kudi No. 2 Machinery's CEP001—has operated smoothly since its acceptance and commissioning in 2019, enduring both winter's harsh cold and summer's heat.

Hunan Wujiang Light Chemical Group Co., Ltd.'s CEP001 continuous blanking production line, built and commissioned in Hami, Xinjiang, is primarily used for mass production of composite metal products. Since its launch, the equipment has operated smoothly year-round, earning high praise from the client.

Due to the production line's advantages of durability, high efficiency, low loss, energy saving, environmental protection, and labor savings, Wujiang Group placed a follow-up order. Kudi No. 2 Machinery and Wujiang Group have now become close partners.

Kudi No. 2 Machinery, striving to be a leader in laser continuous blanking equipment, continues to focus on laser CNC technology and uncoiling blanking processes, resulting in unique technological advantages:

01

The use of variable-speed feeding technology ensures both high productivity and blanking accuracy.

The feeder uses dual servo motor drives to precisely compensate for feeding errors and prevent feeding deviation.

The cutting machine uses belt support to prevent surface scratches on the blanked parts.

The support belt of the cutting machine forms a dynamic light seam under the cutting head, preventing burrs on the edges of the blanked parts.

A stacking platform adaptable to various product specifications allows for quick adjustments during product changes.

Precise feeding and waste separation processes ensure high accuracy and reliability of stacking.

The use of professional nesting software suitable for continuous cutting results in high material utilization.

To date, Kudi No. 2 Machinery has developed a series of products with patented inventions and innovative technologies as its core competitive advantages, capable of providing customized solutions to meet the needs of various industrial enterprises, including automotive interior and exterior sheet metal, steel distribution, cookware, home appliances, sanitary ware, and tableware.

CEP001 Belt-Supported Laser Continuous Blanking Production Line

CEP002 Reciprocating Laser Continuous Blanking Production Line

While constantly innovating, the ambitious Kudi No. 2 Machinery has also reserved upgrade windows for existing equipment, meaning that Kudi No. 2 Machinery's equipment is always upgradeable and at the forefront.

Kudi No. 2 Machinery's factory workshop has physical production lines for CEP001 and CEP002, where you can observe the equipment's actual operation.

Welcome to visit our factory for discussions and experience firsthand the hard-core strength of Kudi No. 2 Machinery's laser blanking equipment, where both appearance and talent are online.