Good News|Kudi's second machine wins the bid for Baosteel New Materials laser production line project

More Good News

Kudi Second Machine and Shanghai Baosteel New Materials Technology Co., Ltd. officially signed a cooperation agreement, reaching an agreement on the leasing business of automotive sheet metal cutting laser blanking lines, and becoming partners.

As one of the mainstream suppliers of automotive thick plates in China, Baosteel New Materials has high requirements for the quality of plate processing and the intelligence of production lines.

For the special process of cutting automotive sheet metal (including thick plates), Kudi Second Machine has mastered the relevant core technologies after nearly a year of research and development.

Affected by the epidemic, Baosteel New Materials' equipment investment pace has slowed down, while the demand for personalized, small-batch, and short-cycle orders has shown a growth trend. Therefore, Baosteel New Materials publicly tendered for the laser production line leasing project.

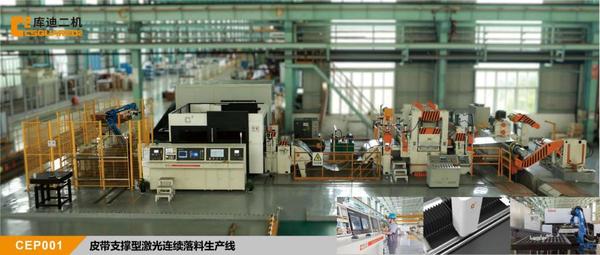

After fully investigating the needs of Baosteel New Materials, Kudi Second Machine designed a customized laser blanking line solution: using Baosteel New Materials' existing two robots and one marking machine, equipped with CEP001 laser continuous dynamic cutting machine and sheet metal positioning equipment, together forming a compact laser blanking line adapted to the processing needs of thick plates.

Thanks to the precise functional design and customized solutions, Kudi Second Machine's laser blanking line solution won the bid!

Kudi Second Machine's Equipment Leasing

In the face of the impact of the epidemic and the needs of industrial enterprises for equipment upgrades, Kudi Second Machine has launched leasing services and introduced financial resources to help enterprises achieve efficient order production with the least start-up capital. For temporary needs, Kudi Second Machine can also provide processing services with supplied materials.

The cooperation with Baosteel New Materials is one of the phased achievements of Kudi Second Machine's leasing business. Its customization and integration have also provided a foundation and experience for the company to serve other manufacturing enterprises.

CEP001 Laser Continuous Blanking Production Line

Applicable Scenarios

1. Industries with high requirements for surface quality, such as automobiles, aluminum products, and stainless steel products.

2. Especially suitable for cutting thick plates and other products with high technical requirements.

Production Line Characteristics

1. Dynamic continuous cutting

2. Following light seam

3. Automatic tool path generation

4. High material utilization rate

5. Belt-type support, ensuring the surface quality of the workpiece, no scratches, no slag on the section, no blackening

6. Mature and reliable robotic stacking scheme, expandable beam, expandable cutting head

7. Precise automatic sheet metal positioning

Product Composition

1. Uncoiling and leveling system

2. Feeding system

3. Laser continuous dynamic cutting machine

4. Material sorting and stacking system

5. Waste material recycling system

6. Auxiliary systems, etc.

Product Functions

1. Automatic uncoiling and leveling of coils

2. Online servo feeding

3. Automatic real-time correction

4. Laser continuous dynamic cutting of workpieces

5. Product sorting and stacking

6. Waste material recycling

......

Important Parameters

1. Feeding speed: 0-25 meters/minute

2. Number of cutting heads: 1 (multiple cutting heads can be configured according to production capacity requirements)

3. Positioning accuracy: 0.03mm

4. Laser power: 1500-6000w

Guangdong Kudi Second Machine Laser Equipment Co., Ltd. was established in 2017 and is a technology-innovation-oriented enterprise dedicated to the research and development, production, and sales of laser continuous blanking equipment. The company has deep brand accumulation and technical strength, relying on a fully independent intellectual property rights CNC system, and has always adhered to independent innovation in the field of laser blanking. It has now obtained 6 patents, obtained Guangdong Provincial High-tech Products, and has been listed as a qualified supplier by Baosteel Group.

In July 2018, the company launched China's first belt-supported laser continuous blanking equipment, which has performed well in the market and has successively launched a number of laser blanking equipment, becoming one of the domestic manufacturers with the most complete series of laser blanking products and solutions. Currently, Kudi Second Machine's laser continuous blanking equipment can be widely used in automotive interior and exterior sheet metal, metal coil opening and distribution, cookware, home appliances, sanitary ware, tableware, and other industrial fields.

Welcome partners from all walks of life to inquire and discuss

Tel: 15862886566 (Sales) / 400-0128-365 (After-sales)

RELATED POSTS

Flash | Kudi's second plant becomes a council member of Guangdong Laser Industry Association