Third Anniversary |初心不忘,砥砺前行

On October 9, 2017, Guangdong Kudi Erji Laser Equipment Co., Ltd. was officially established.

The company's technical team was established in 2012 and has been focusing on CNC systems for years.

Driven by independent research and development and technological innovation, Kudi Erji has gradually grown into a leader in the field of laser blanking equipment with a low-key and pragmatic, and constantly striving spirit, achieving numerous fruitful results along the way.

Technology

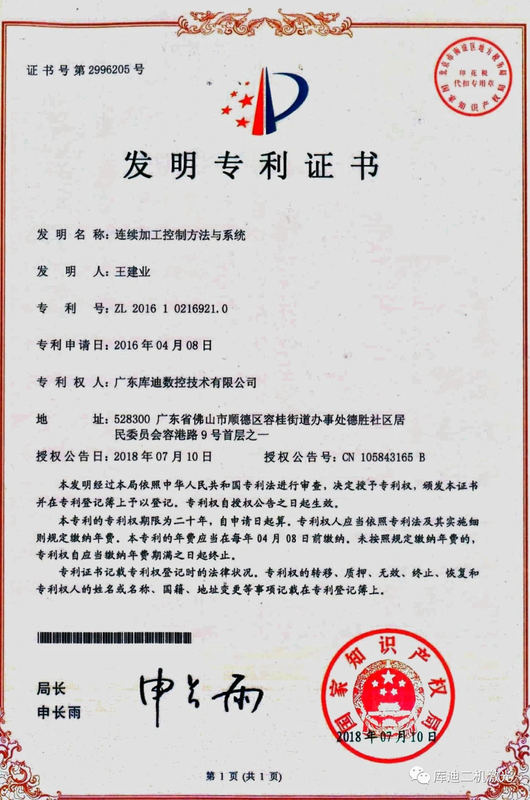

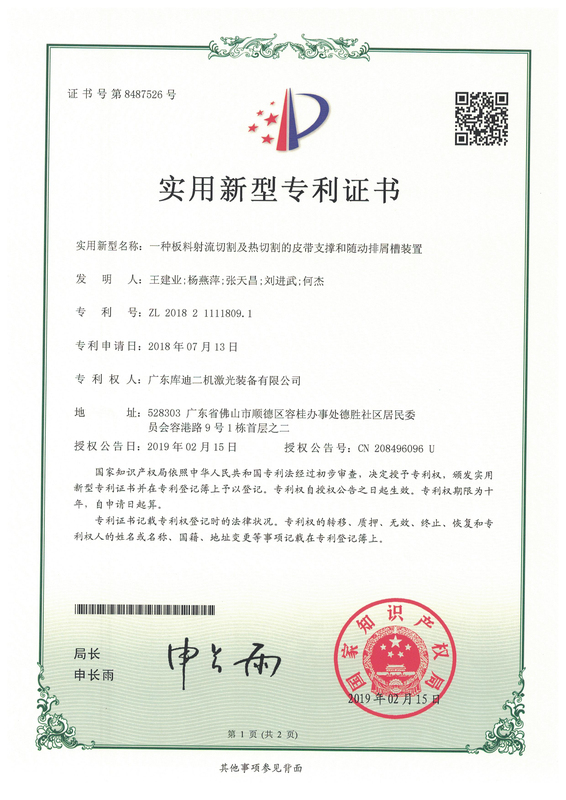

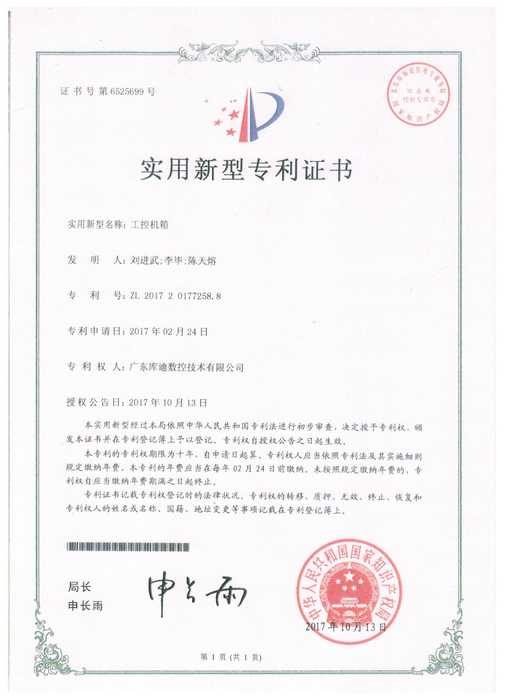

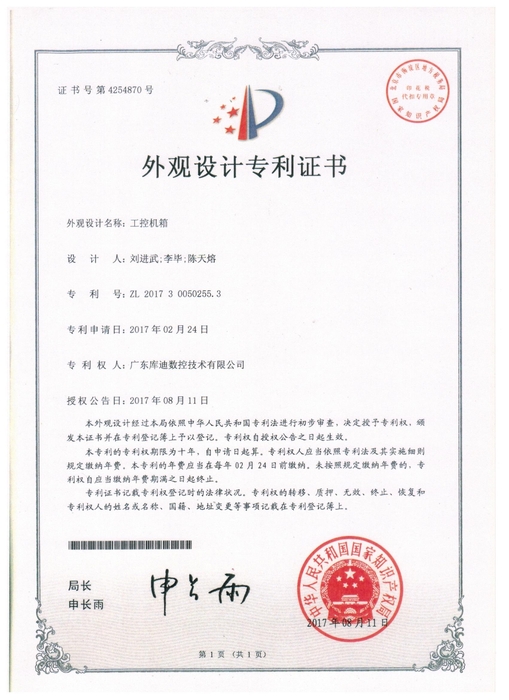

Kudi Erji always regards independent research and development and technological innovation as the foundation of its establishment and development.

The CNC system development team Since its establishment in 2012, has been conducting in-depth exploration and practice around laser CNC technology and uncoiling blanking technology, and has obtained a number of patents.

In 2020, Kudi Erji's world's first single-beam dual-cutting head technology was launched.

With the configuration of dual cutting heads and multiple cutting heads, the production capacity of laser blanking equipment will be doubled.

Products

Since its establishment, Kudi Erji has launched three laser blanking equipment characterized by intelligence, flexibility, and customization.

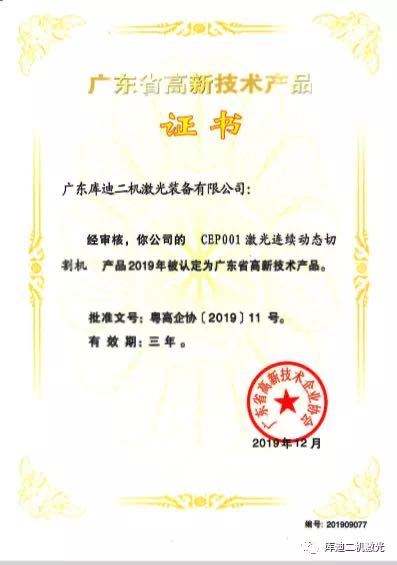

CEP001

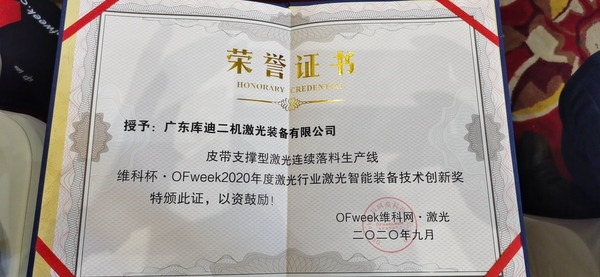

Belt Support Type Laser Continuous Blanking Production Line

As China's first belt support type laser continuous blanking production line, CEP001 has won numerous awards.

CEP001 is suitable for Automobiles, aluminum products, stainless steel products and other industries with high surface quality requirements. Its main features are

Dynamic continuous cutting

Belt-type support

Following light seam

Non-destructive cutting, the workpiece surface is free of scratches and stains, the cutting seam is free of burrs and has small burrs

Automatic tool path generation

Mature and reliable robotic stacking scheme

Expandable beams, expandable cutting heads

High material utilization rate

CEP002

Reciprocating Laser Continuous Blanking Production Line

CEP002 is hailed by the industry as "Laser blanking heavy weapon" 。

Suitable for Home appliances, cookware, kitchenware, stainless steel products and other industries' sheet metal blanking, the main advantages are:

Dynamic continuous cutting

Innovative steel roller support structure, the cutting material reciprocates, and the cutting beam remains stationary

The laser cutting head only moves in the Y-axis direction, and large workpieces can be effectively cut without a cutting platform

Equipped with a metal coil automatic feeding system to achieve efficient automated production

Small product footprint and low cost

CEP003

Rolling Tooth Plate Type Laser Continuous Blanking Production Line

CEP003 is suitable for Steel distribution, general sheet metal blanking, home appliances, etc. fields. The main advantages are:

· Step-by-step or continuous cutting

· The cutting machine tooth plate table can realize rolling feeding, replacing the stationary table of ordinary cutting machines, effectively improving feeding and cutting efficiency

· Multiple beams and multiple cutting heads for efficient and fast cutting

· The cutting process can be simply connected to the uncoiling and leveling process of the steel coil to form a smooth and continuous production line

· Automatic material picking and waste material winding to improve material utilization rate

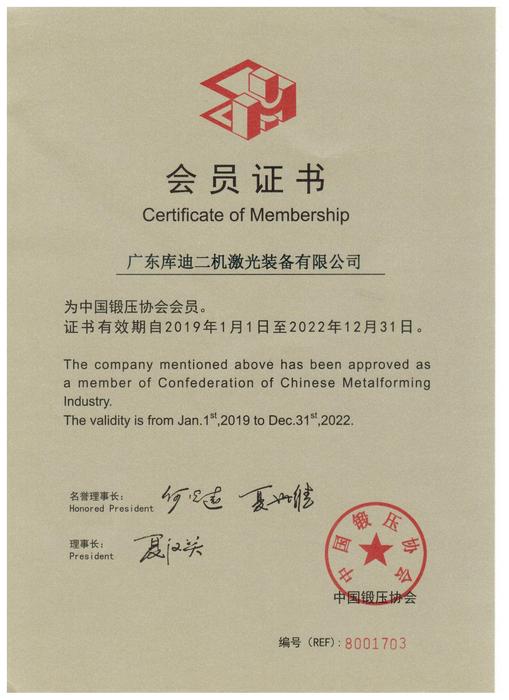

Honors

Kudi Erji focuses on technology, and strictly controls products and management, and has been widely recognized by the industry and the market.

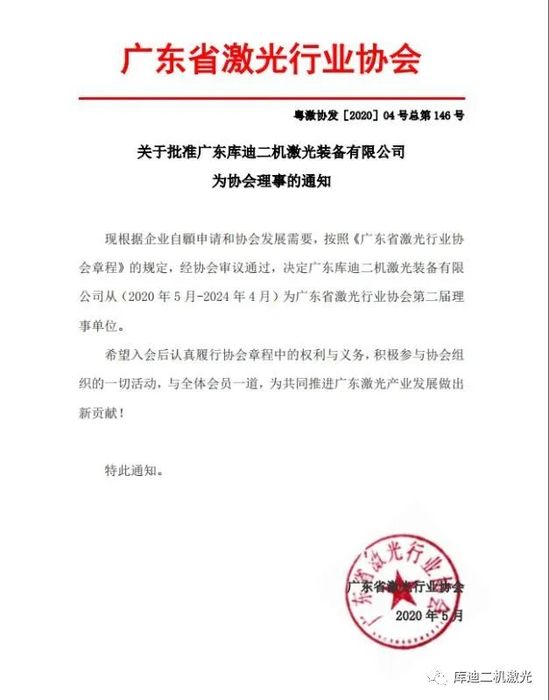

Currently, Kudi Erji has successfully passed ISO9001 Quality Management System audit certification, becoming Member unit of the China Forging and Pressing Association and director unit of the Guangdong Laser Industry Association , and was also rated by the Foshan Municipal Market Supervision and Administration Bureau as a "Contract-Honoring and Credit-Valuing Enterprise".

Development Overview

Kudi Erji, adhering to its principles and looking ahead, has also received attention and support from leaders, experts, and partners from all walks of life on its path of meticulous cultivation.

From the rudimentary and difficult early days of its founding to the recent new product launch conference and technical seminar, Kudi Erji is thriving.

High-quality products and services have earned Kudi Erji market favor.

Cooperation

Kudi Erji has established long-term and friendly partnerships with numerous companies in the industry.

Major cooperating units include: BaoWu Group, Aishida, Schneider Electric, Wujiang Light Chemical Group, Yaskawa Industrial Robots, Delta Electronics, IPG Group, Lecong Steel World, Wanfeng Metal, Dongyang Weaving Net, Sansha Cookware, etc.

After more than a thousand days and nights of perseverance and hard work, Kudi Erji is showing signs of flourishing growth.

The abundant fruits of labor are both achievements and encouragement. Kudi Erji will always adhere to its original aspirations, continue to exert efforts in the field of laser continuous blanking equipment, strive to empower industrial transformation, and contribute to China's intelligent manufacturing.

RELATED POSTS

Flash | Kudi's second plant becomes a council member of Guangdong Laser Industry Association