Device + strategy shows significant results, customer placed additional orders

Kudi Erji, a manufacturer of laser continuous blanking equipment, why has its workshop recently become a coil processing plant?

(Customer-supplied material processing of coils | Location: Kudi Erji factory)

(Processed parts awaiting shipment | Location: Kudi Erji factory)

Kudi Erji's vision of becoming a leader in laser continuous blanking equipment remains unchanged! It's just that the path to achieving this is more diverse and innovative.

Laser continuous blanking is a new production process in China and even globally. Due to the high cost of imported equipment and the lack of domestic technology, this technology has not been widely applied to various industries in China. A common misconception among users is that domestic laser blanking equipment is immature, consisting of separate traditional uncoiling and straightening equipment paired with a flat cutting machine, not a production line concept, and unable to achieve stable feeding, cutting, and stacking in a continuous line.

To break this inertial misconception, Kudi Erji formulated a "equipment +" strategy in 2020, establishing a processing department under the marketing department, and investing in two CEP001 and CEP002 laser continuous blanking demonstration lines in the factory. More than 200 tons of coils have been processed to date. It is hoped that within 1-2 years, by increasing promotion efforts, customers will be able to see the stable and efficient production status of Kudi Erji equipment at our factory. To let customers know that there is also reliable belt-supported laser continuous blanking equipment in China. Kudi Erji is both "late" and "early" in the laser industry.

Kudi Erji missed the golden ten years of rapid development in China's laser industry, but it has identified and seized the opportunity of laser continuous blanking.

Through reverse thinking, in 2015, by developing a continuous cutting CNC system, mastering core technologies, and launching a laser continuous blanking production line in 2017, the entire line is controlled by linkage interpolation, with characteristics of high speed, material saving, flexibility, and no scratching, especially suitable for automotive interior and exterior sheet metal, kitchenware, and other industries with high surface quality requirements.

To date, more than 10 laser blanking lines have been signed.

In 2020, the "equipment +" strategy achieved its expected results. At the beginning of 2020, Foshan Dingyu Metal Products Co., Ltd. ordered a CEP001 belt-supported laser continuous blanking production line from Kudi Erji.

Less than two months after the delivery of the first production line, Foshan Dingyu Metal Products Co., Ltd. placed another order for Kudi Erji's new product: a 1600mm single-beam double-cutting head CEP001 belt-supported laser continuous blanking production line.

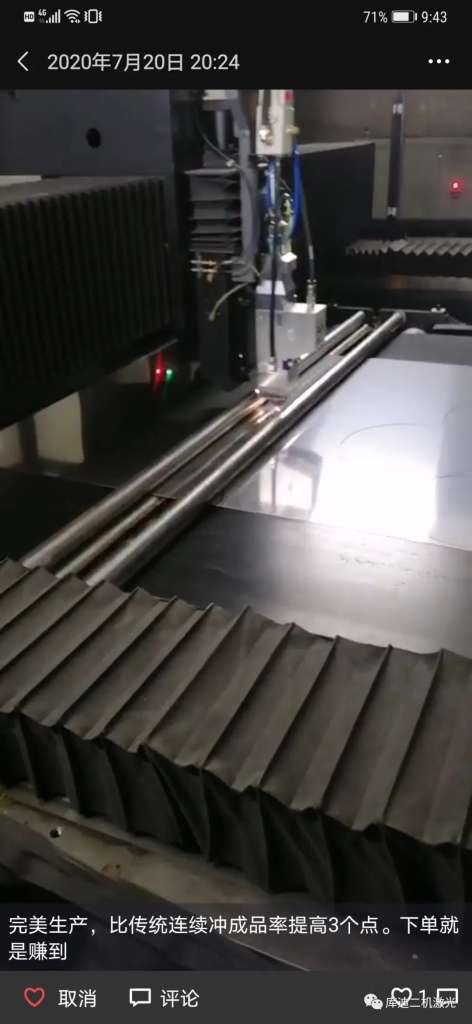

(Screenshot of customer feedback WeChat)

Since the completion of installation and commissioning, the production line of Foshan Dingyu Metal Products Co., Ltd. has been operating continuously day and night.

(Screenshot of customer feedback WeChat)

The CEP001 belt-supported laser continuous blanking production line can fully realize the functions of traditional molds during production. With just the press of a button, it can quickly switch between processing different shapes of sheets, with extremely high material utilization. While saving labor costs, it improves processing efficiency. Due to high processing accuracy, burr-free sheets, no need for edge grinding, no scratches, and stable and reliable product quality, Foshan Dingyu Metal Products Co., Ltd.'s orders have surged, and its market share has continued to expand.

Facing a booming market, Foshan Dingyu, after inspecting the CEP001 single-beam double-cutting head demonstration line at the Kudi Erji factory, ultimately led to a second collaboration.

Kudi Erji's pioneering single-beam double-cutting head technology only increases investment by less than 10%, but achieves 1.5-2 times the production capacity, bringing significant economic benefits to customers.

In the post-pandemic era, Kudi Erji's laser continuous blanking production line is strongly promoting the rapid market seizure and accelerated development of automotive, home appliance, cookware, and other sheet metal processing enterprises.

Guangdong Kudi Erji Laser Equipment Co., Ltd., established in 2017, is a technology-innovation-oriented enterprise focusing on the research, development, production, and sales of laser continuous blanking equipment, committed to becoming a leader in laser continuous blanking equipment.

The company has deep brand accumulation and technical strength, relying on a fully independent intellectual property rights CNC system, and has always adhered to independent innovation in the field of laser blanking. It has obtained 6 patents, won the Guangdong Provincial High-tech Product award, and has been listed as a qualified supplier by Baosteel Group.

In July 2018, the company launched China's first belt-supported laser continuous blanking equipment, which has performed well in the market, and has subsequently launched a number of laser blanking equipment, becoming one of the domestic manufacturers with the most complete series of laser blanking products and solutions.

Currently, Kudi Erji's laser continuous blanking equipment can be widely used in automotive interior and exterior sheet metal, metal coil opening and distribution, cookware, home appliances, sanitary ware, tableware, and other industrial fields.

Welcome partners from all walks of life to inquire and discuss.

Tel:

15862886566 (Sales) / 400-0128-365 (After-sales)

RELATED POSTS

Flash | Kudi's second plant becomes a council member of Guangdong Laser Industry Association