New Product Recommendation | Online Analysis of CEP002 Reciprocating Laser Continuous Shearing Production Line

In the post-epidemic era, the industry landscape and market demand have undergone profound changes. Orders for multi-variety, small-batch, and flexible customization have significantly increased. To adapt to market changes and meet customer needs, Kudi Second Machine launched the CEP002 reciprocating laser continuous blanking production line.

As a new product launched by Kudi Second Machine, CEP002 is a moldless intelligent laser blanking system suitable for mass production . It features low overall investment, short production preparation cycle, high flexibility, high quality of sheet metal processing, continuous optimization of product geometry and precision, high material utilization rate, and cost savings. The functions and technical parameters of the production line can also be customized according to customer needs.

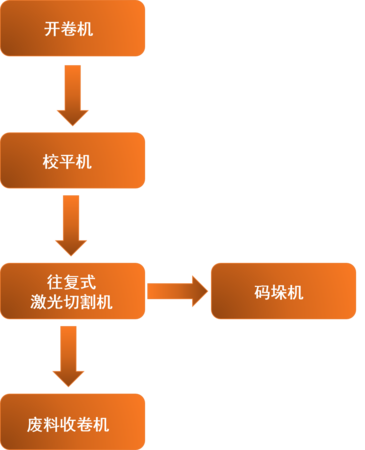

Equipment Composition and Process Flow

Production Line Features

Equipped with a metal coil automatic feeding system to achieve efficient automated production

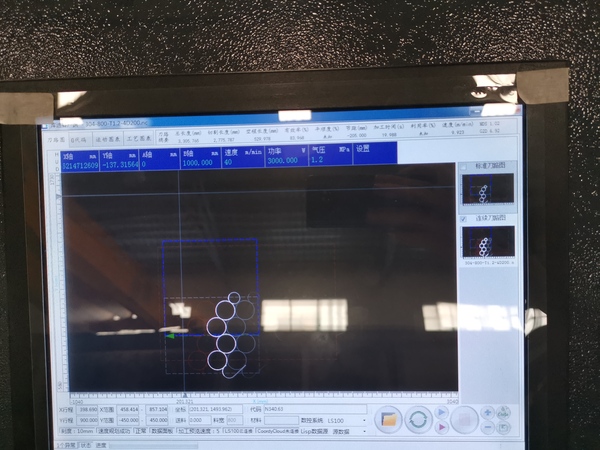

Innovative steel roller support structure, reciprocating movement of cutting materials, and fixed cutting beam

The laser cutting head only moves in the Y-axis direction, enabling effective cutting of large workpieces without a cutting platform

Small footprint and low cost

Project Parameters

Applicable Scenarios

CEP002 is especially suitable for sheet metal blanking in the home appliance , kitchenware, and cookware industries, and is also particularly suitable for production processes that require frequent product changes.

Since the launch of CEP002 , it has received market favor and widespread praise. Currently, the first set of orders has been formed, and the demonstration line in the factory will also begin to undertake various processing order businesses on June 15.

RELATED POSTS

Flash | Kudi's second plant becomes a council member of Guangdong Laser Industry Association