Kudi Cloud empowers equipment upgrades, promoting intelligent production

|

Cloud platforms can efficiently connect various production factors such as enterprises, equipment, materials, and personnel, forming a design and manufacturing ecosystem characterized by real-time sharing and efficient operation. They are a necessary means of connecting intelligent manufacturing and promoting industrial transformation and upgrading.

Kudi Erji, a company founded on innovation, has devoted its efforts to creating the Kudi Cloud platform. Currently, the Kudi Cloud is operational and has created physical models of intelligent production and digital workshops for its partner clients.

The Kudi Cloud, developed by Kudi Erji, utilizes cloud computing and Internet of Things (IoT) technologies. Cloud computing ensures uninterrupted and secure IoT services with low-cost investment. Users are no longer limited by geographical location and can access the latest information anytime, anywhere.

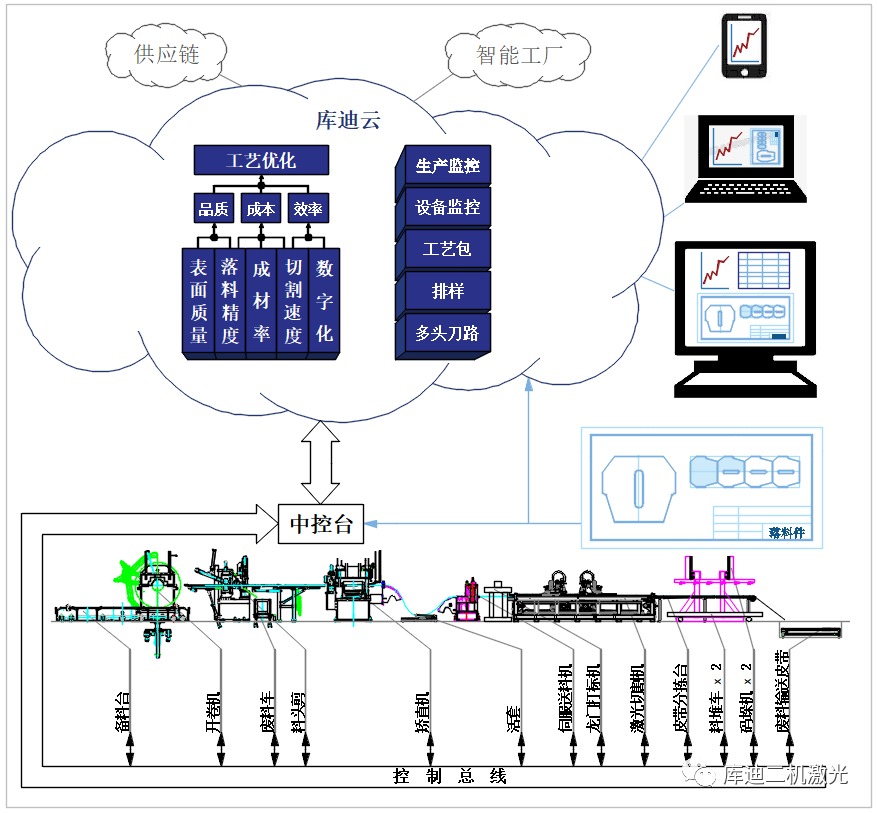

The Kudi Cloud consists of a device layer, gateway, cloud platform, and application service layer. The device layer includes physical sensors and actuators used for data acquisition and control; the gateway enables communication between the cloud platform and devices; the cloud platform communicates with the gateway, acquires data, stores it in time-series and structured formats, and performs processing and analysis; the application service layer integrates with other systems and applications (such as ERP) to enable data exchange between applications.

The Kudi Cloud structure is shown in the diagram above.

The Kudi Cloud gathers various types of data, including data collected from production lines, data from management information systems, and data from external connections, including data from users and collaborating companies. It achieves lossless digital mapping and description of physical objects such as equipment and production lines, as well as processes and manufacturing workflows. After the completion of the Kudi Cloud, firstly, it promotes information interaction between management systems, such as design systems, production management systems, customer relationship management systems, and supply chain management systems; secondly, it promotes comprehensive data sensing and collection, including the collection of operating status information and production environment information during the production process; thirdly, it promotes data integration and analysis, realizing production control and various intelligent management decision-making applications; fourthly, by deploying edge computing nodes, it realizes edge data analysis and processing to meet the needs of real-time control and data security; fifthly, through external interconnection, it gathers product data, user data, environmental data, and collaborative enterprise data, and utilizes big data technology to achieve comprehensive storage, analysis, and processing of massive and complex data. The Kudi Cloud in the laser blanking production line Plays an important role: It performs comprehensive analysis of blanking line operating data to identify optimal parameters in the production process. It conducts correlation analysis and big data optimization based on product inspection data and process data such as "man-machine-material-method-environment," enabling online quality monitoring and anomaly analysis, reducing product defects, and improving manufacturing quality and the quality of blanked parts. During production, by analyzing data on production progress, material management, and enterprise management, it improves the accuracy of scheduling, progress, material, and personnel management, thereby increasing blanking production efficiency. Based on the collection and analysis of on-site energy consumption data, it enables rational planning of blanking line energy efficiency, establishing energy equipment management, production energy consumption analysis, and energy event management, improving energy use efficiency, achieving energy saving and emission reduction, and reducing blanking production costs. It monitors the operating status, processing status, production progress, and efficiency of the blanking line. Combining data summary analysis, it analyzes and diagnoses potential impacts on the blanking line, providing decision-making support to dispatchers for dynamic scheduling and emergency handling of the production process, ensuring stable and efficient operation of the blanking line. The Kudi Cloud reflects production progress, material consumption, and processing information in real time and dynamically. It can be displayed through various channels (large screens, computers, mobile devices, etc.). Users can access system resources and handle various tasks simply through a web browser. |

RELATED POSTS

Flash | Kudi's second plant becomes a council member of Guangdong Laser Industry Association

、

、