For automotive sheet metal laser cutting, I choose Kudi secondary equipment.

|

Recently, the workshop at Kudi's No. 2 factory is bustling with activity. A CEP001 belt-supported continuous blanking production line, equipped with a double-cutting head, is carrying out high-strength steel automotive sheet blanking and processing operations in an orderly manner. As an equipment manufacturer, Kudi's No. 2 factory has a physical equipment production line in its factory workshop. By providing "processing with supplied materials" services, it helps customers more intuitively and vividly experience the performance and quality of Kudi's No. 2 factory's equipment. After visiting and understanding, the automotive parts company signed a contract with Kudi's No. 2 factory for a total of over 100 tons of automotive sheet processing orders. This poses stringent requirements on Kudi's No. 2 factory's mass production capacity of laser blanking equipment, flexible processing capabilities, and efficient non-destructive cutting. So, what kind of answer did Kudi's No. 2 factory give? Since the signing of the project, through Kudi's No. 2 factory's professional technical team's comprehensive design of the overall solution, further optimizing the cutting process, in just 7 days, it not only completely exceeded the customer's production capacity needs, but the overall non-destructive cutting (no scratches, no dust, etc.) and process quality also exceeded customer expectations.

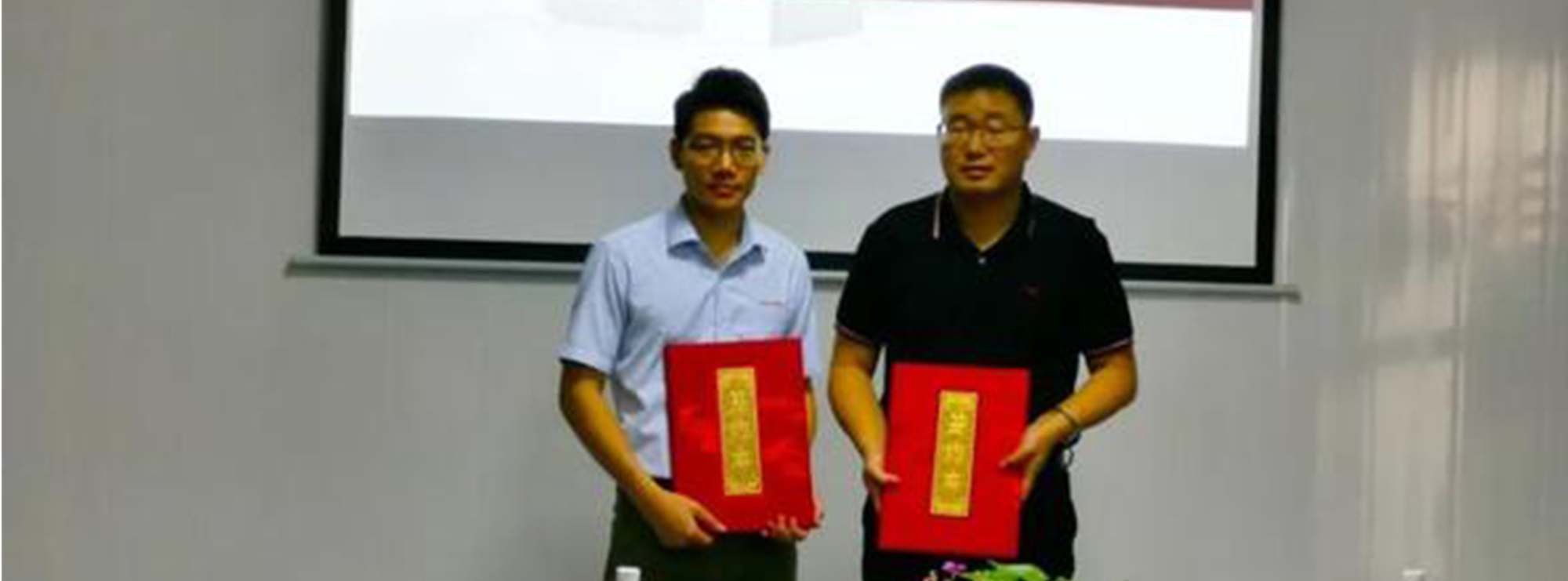

(On-site picture)

Kudi's No. 2 factory, dedicated to laser blanking technology and uncoiling blanking processes, can provide complete laser blanking solutions and rapid response after-sales service for sheet metal processing enterprises, especially those in the automotive industry. Welcome partners from all walks of life to visit Kudi's No. 2 factory for visits and discussions. |

RELATED POSTS

Flash | Kudi's second plant becomes a council member of Guangdong Laser Industry Association